DESCRIPTION

TECHNICAL SPECIFICATIONS

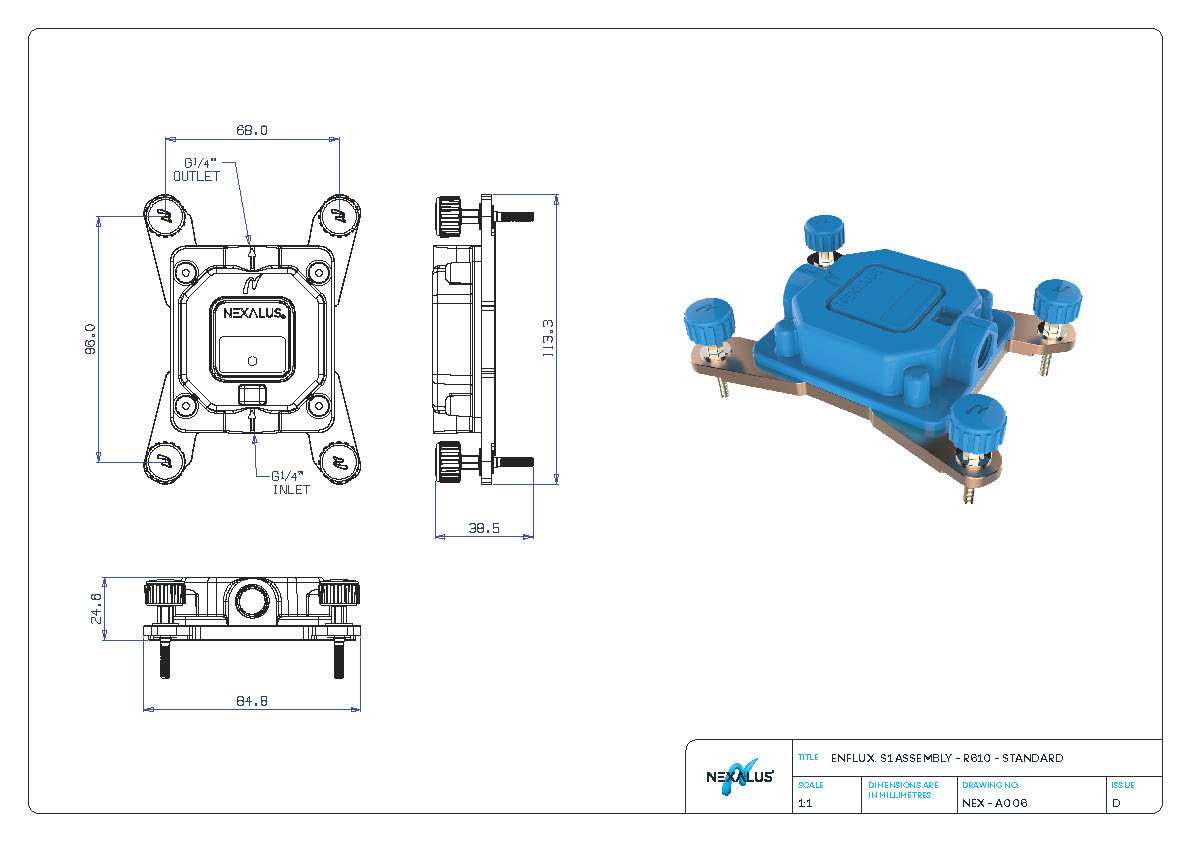

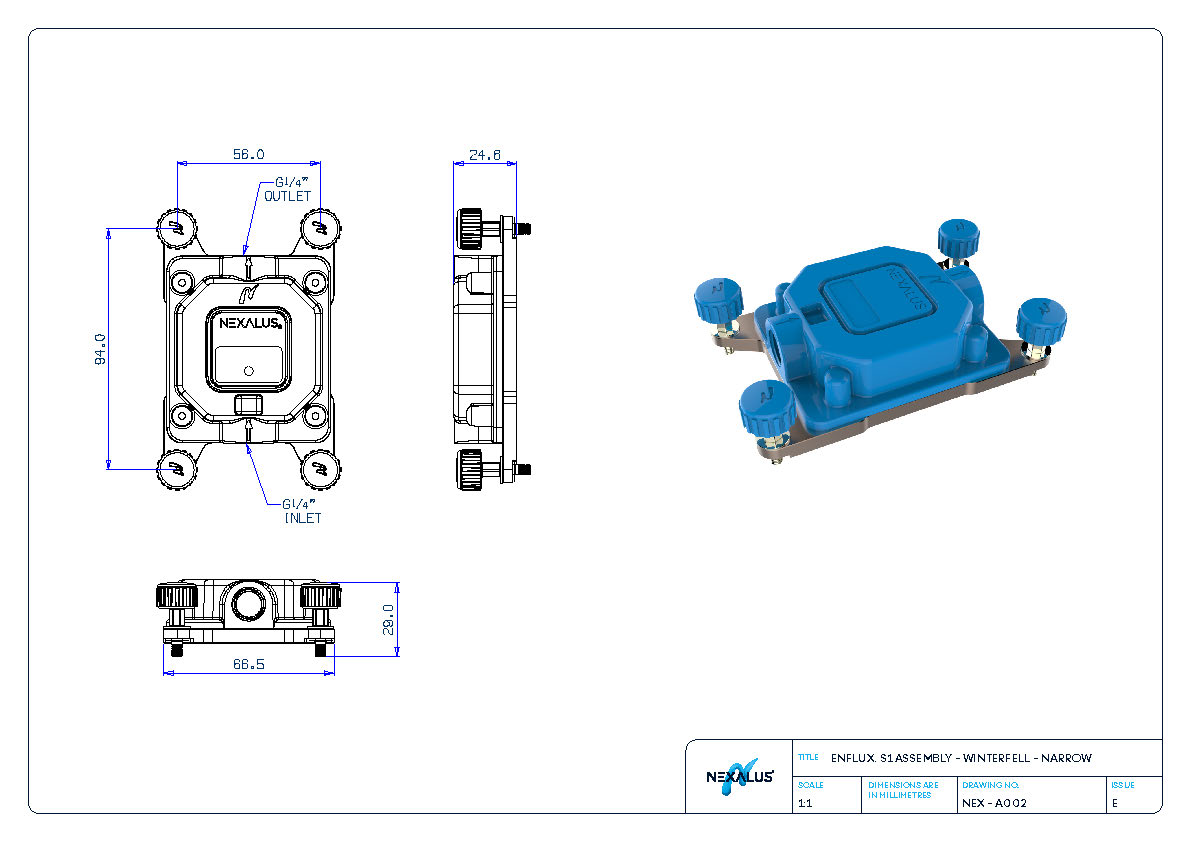

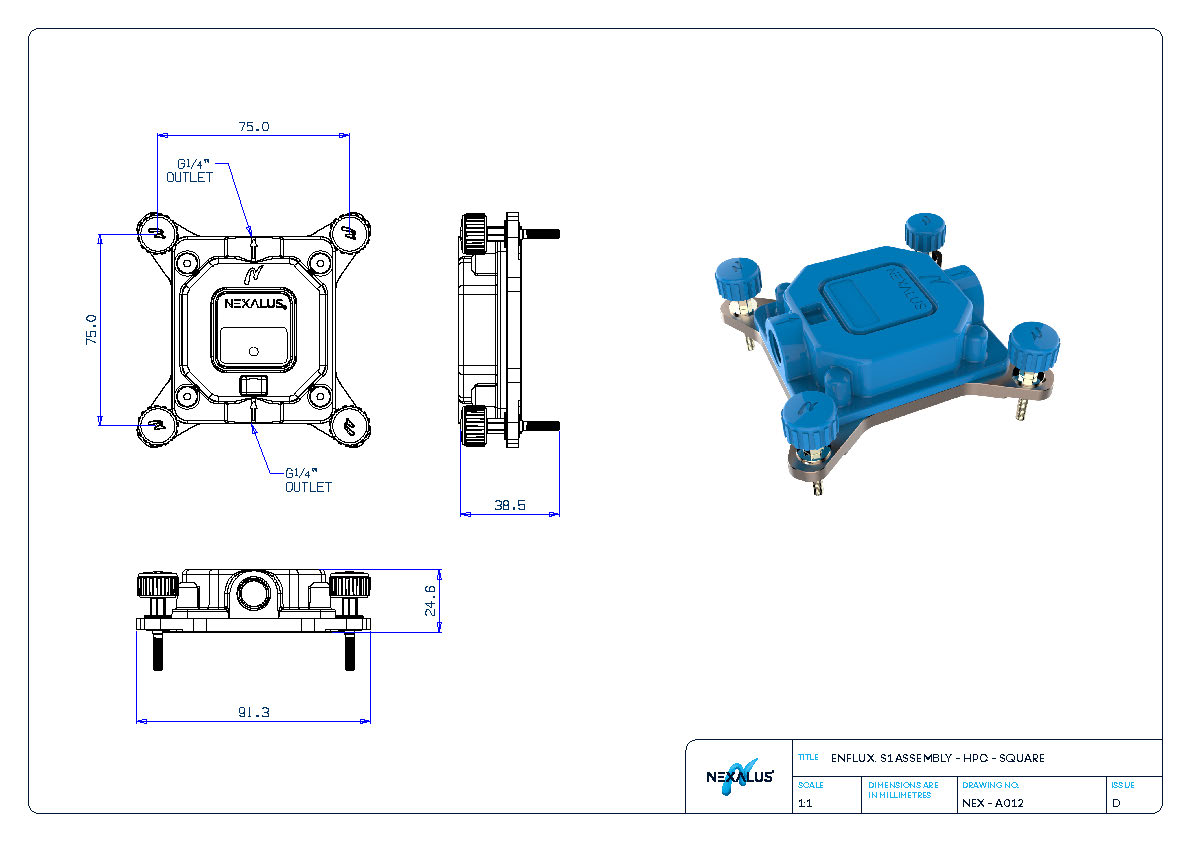

DRAWINGS

DESCRIPTION

DESCRIPTION

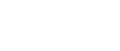

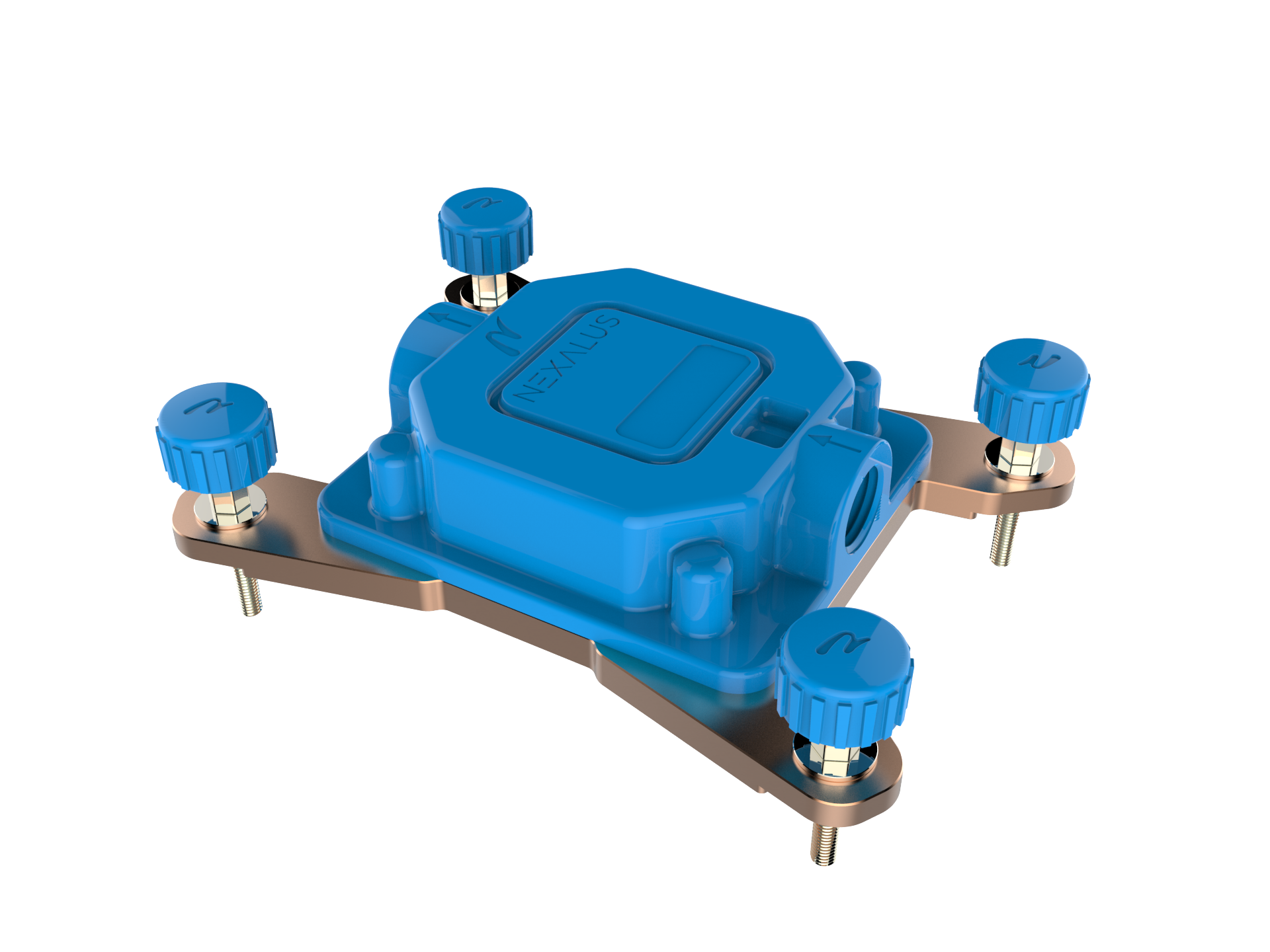

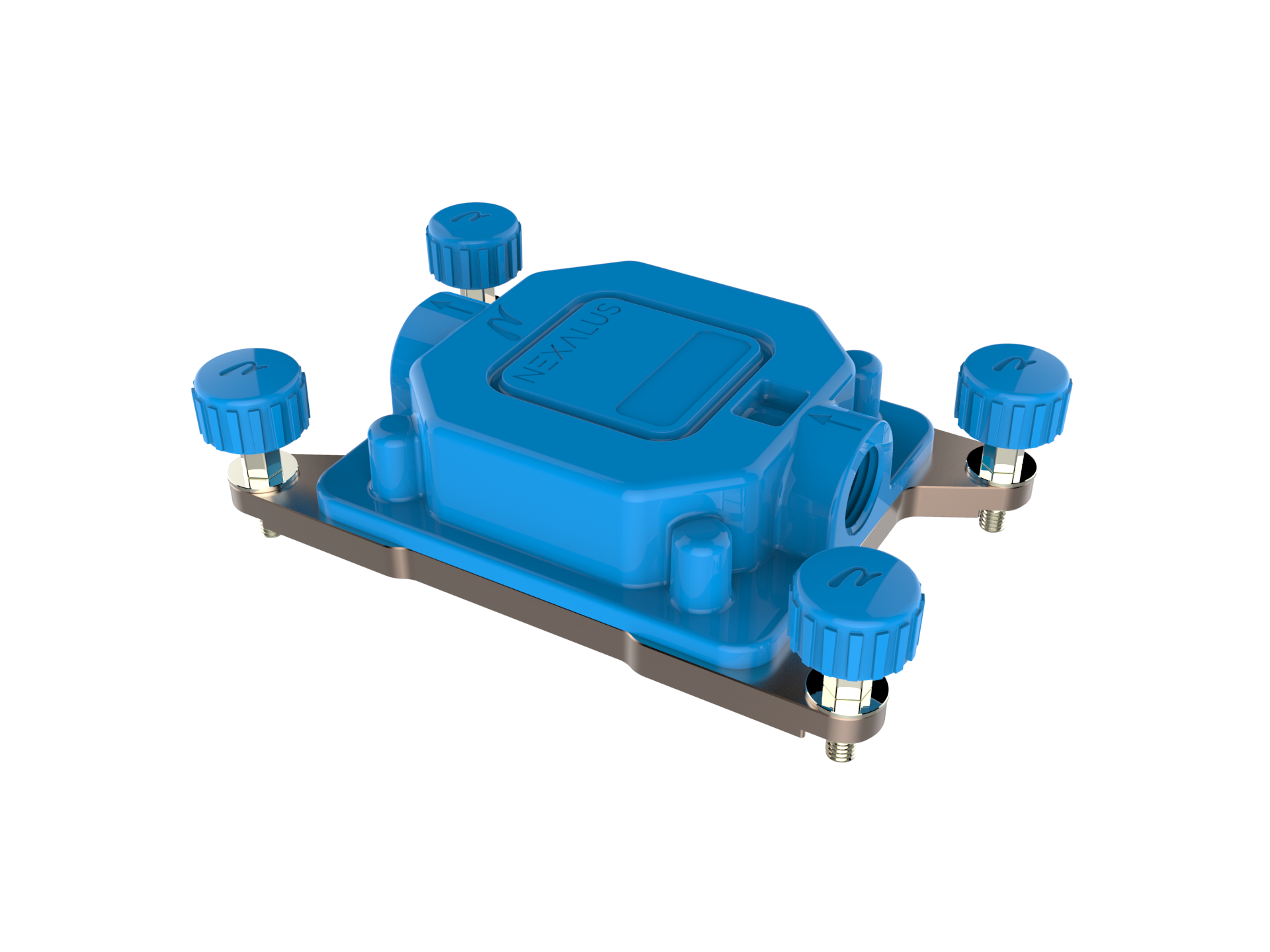

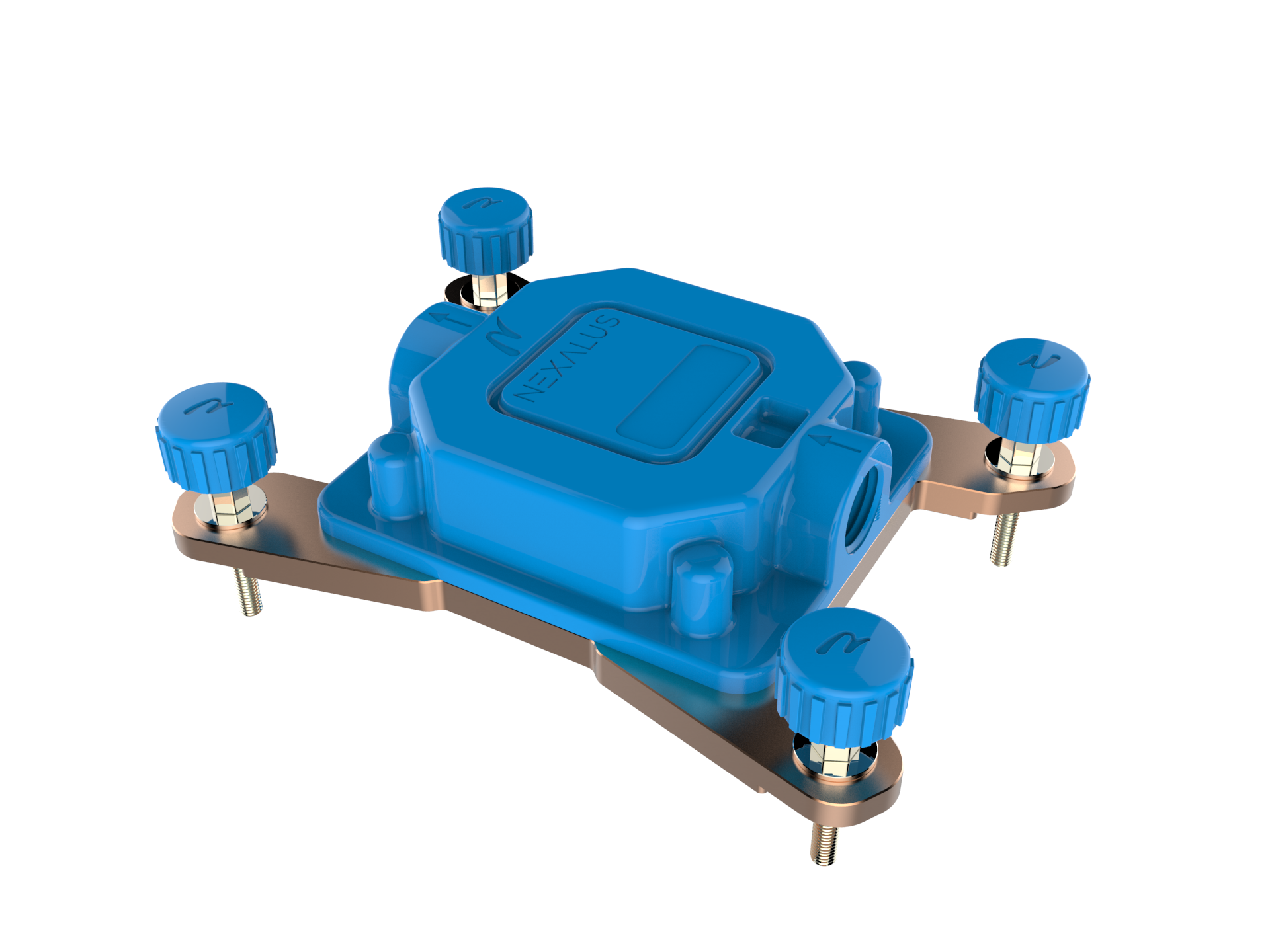

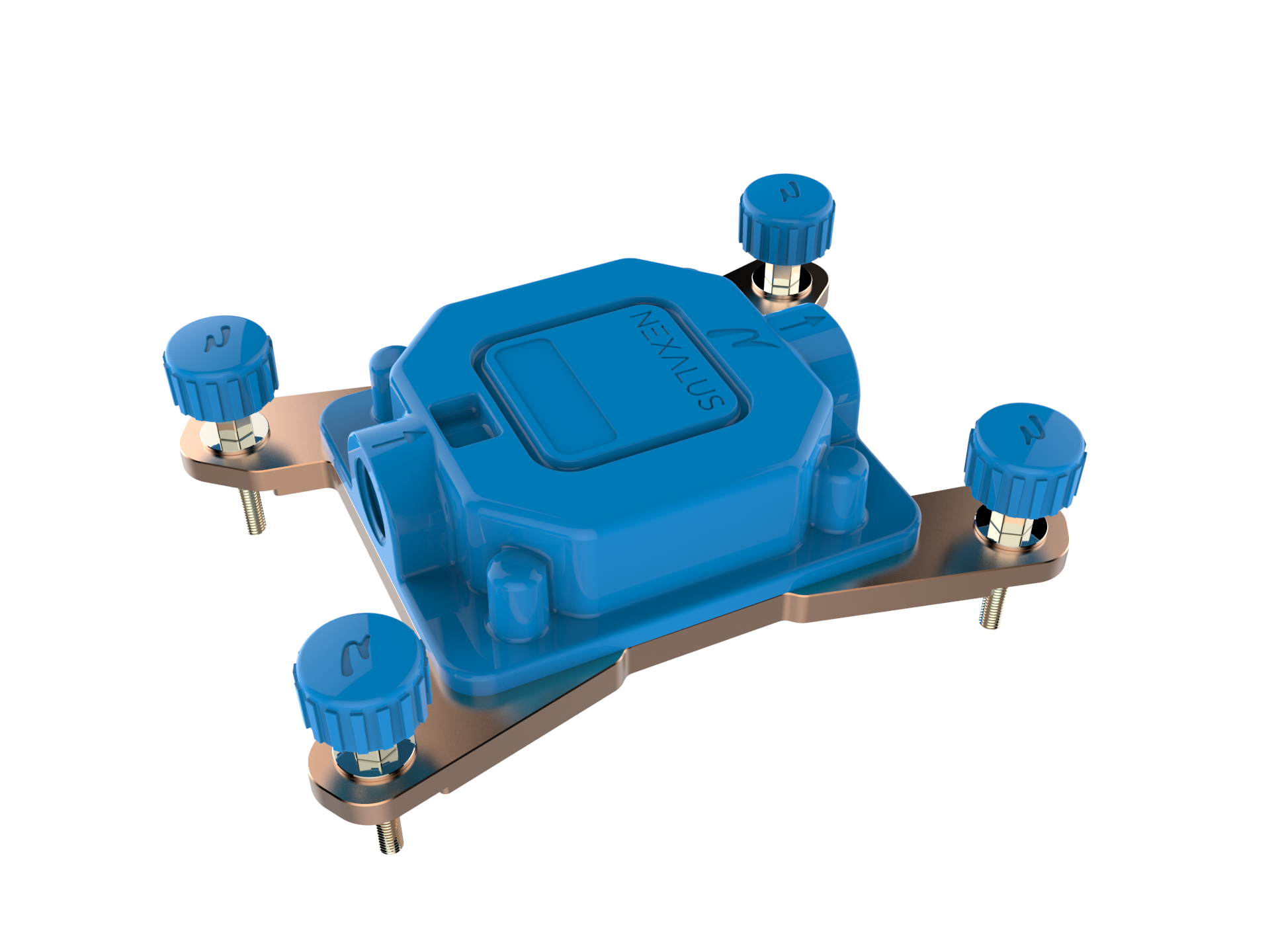

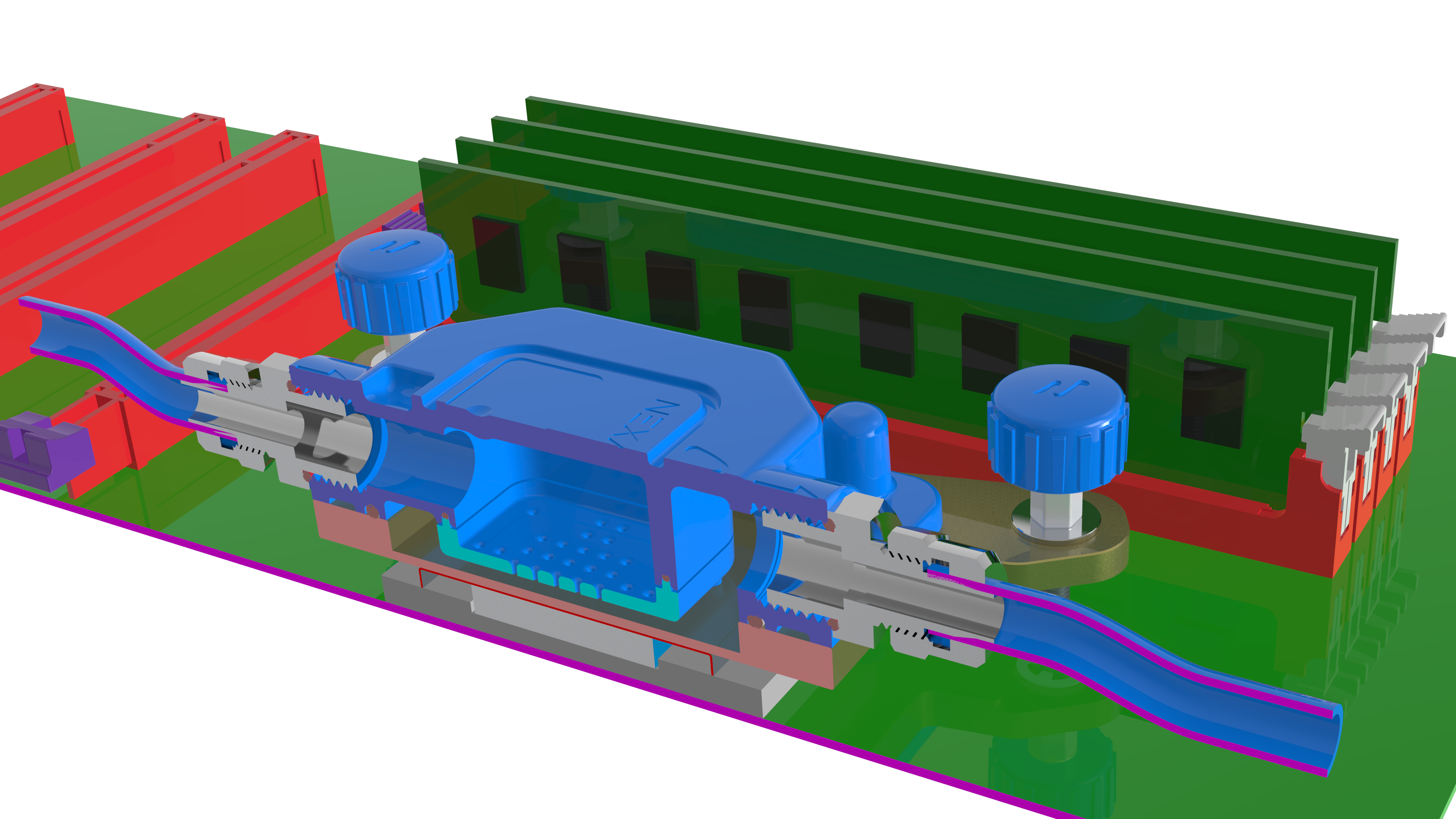

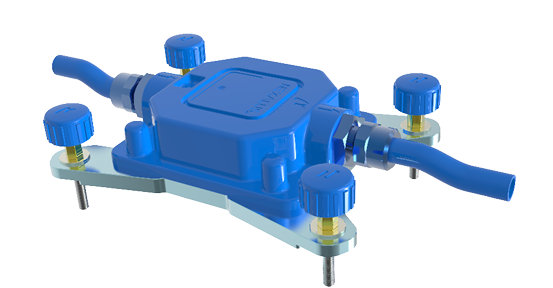

A high-end engineered CPU water block introduced in 2020 which was designed for server-based applications with the Xeon chipset. More than two years’ worth of research, design, experimentation, testing, and redesign now results in the highest performing water block on the market for 1U server applications where space is of a primary concern.

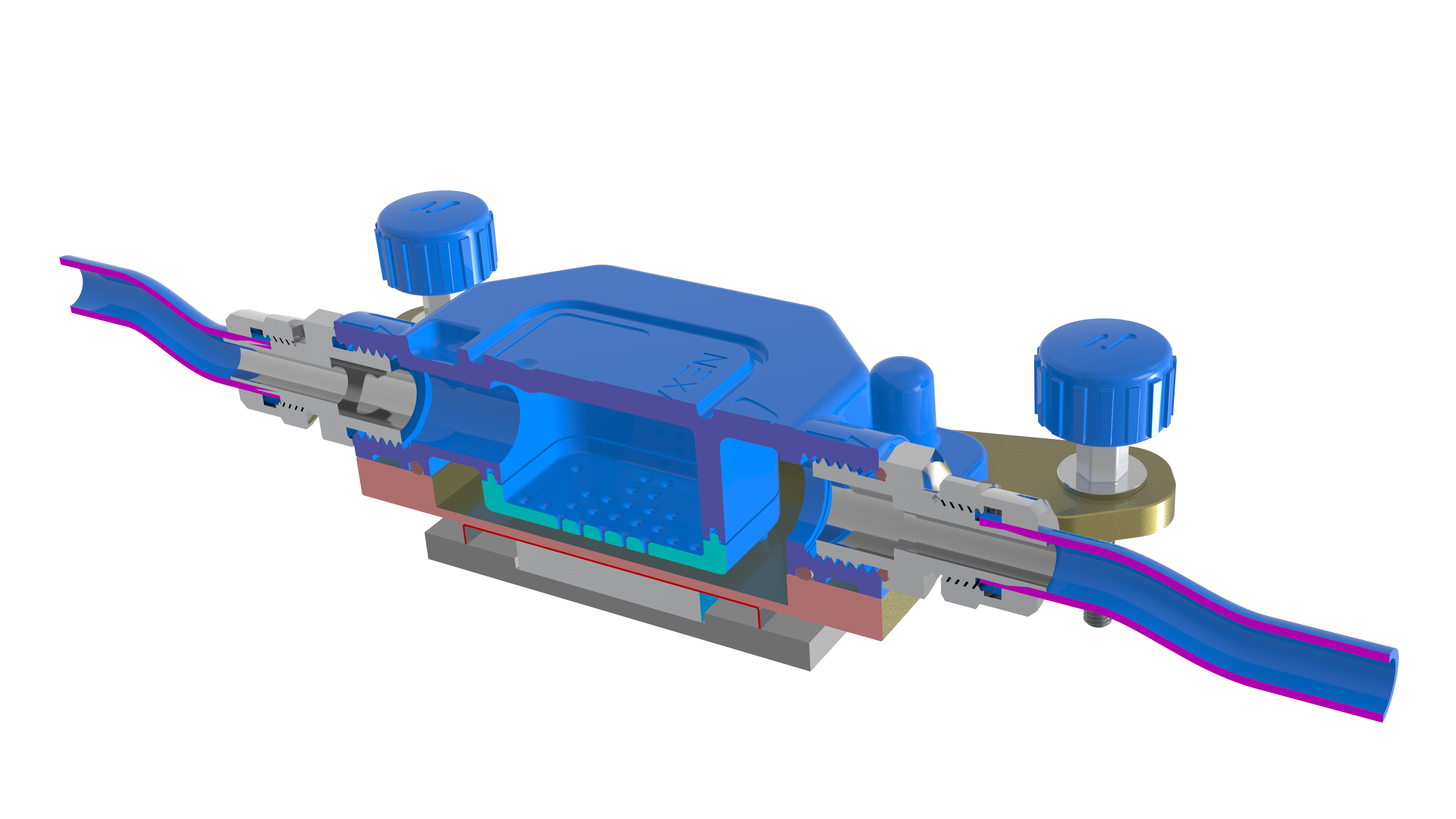

Manufacture: The manifold is fabricated by injection moulded Trirex 3020U Polycarbonate at Mergon International in two parts (the main body and shower head). The base plate is fabricated using pure copper which is first machined with high precision and then polished to a mirror finish. Finally, the copper is Electroless Nickle plated to provide corrosion and wear resistance.

Scientific approach: The water block is based on the use of impinging liquid jets due to this cooling techniques very high heat transfer coefficients and targeted cooling which can be directed at the hottest parts of the integrated heat sink. The nozzles were tested for a Reynolds number range of approximately 5000 ≤ Re ≤ 10,000 to reach heat transfer coefficients of 30-40 kW/m2K. The locations of the jets were tailored to suit the positions of the CPU cores so that cool water is directed towards the hottest areas of the CPU’s integrated heat sink. After a thorough investigation of a range of jet configurations including nozzle diameter, nozzle to target spacing and nozzle length, the highest performing shower head was chosen to cool the CPU. The inlet water flows into the side of the upper chamber, which homogenised the flow to deliver a uniform Reynolds number and heat transfer coefficient across each jet.

Note: The current shower used in Nexalus S1 (star pattern) was chosen to fit a wide range of CPUs. Each showerhead can be customised to cool a specified CPU to further improve performance.

TECHNICAL SPECIFICATIONS

TECHNICAL SPECIFICATIONS

Thermal interface material (TIM): The thermal interface material (TIM) has a significant impact on the performance of the cooling system and can decrease the performance by over 5°C if the TIM is not applied correctly. The Hydronex thermal grease was chosen to make the thermal transfer between the IHS and the copper plate as this product has a very low thermal resistance and provides a reduction in CPU temperature by 1-2°C in comparison to other leading thermal greases on the market. A low viscosity allows this grease to be readily applied to the CPU, providing consistent performance after each application.

This thermal grease reacts to the heat providing by the chip and is spreading to leave only the amount needed for best performance. With this thermal grease, the performance will not vary significantly from application to application.

Torque screws:The torque screws were optimised for a range of water block and CPU combinations in order to deliver the ideal force to the CPU. The torque screw mechanism allows the install of the water block by hand and without the need for additional tools, i.e. a tool-less installation.

The main features are:

• Engineering design: High heat transfer coefficient targeted at the CPU cores.

• Unmatched thermal performance: more than 2°C better performance on Intel processors than other market leaders in CPU cooling.

• Tool-less installation: The torques screws make the water block user friendly, ensuring the correct pressure is applied on the IHS.

Socket Compatibility:

– Intel LGA-1150/1151/1155/1156

– Intel LGA-2011 , LGA-2011v3 square ILM

– Intel LGA-2066

Enclosed:

– Nexalus S1 water block

– TIM / Thermal Interface material: Hydronex (1g)

– Torque screw

Additional info

| Component | Information |

| Plate | Copper (Nickel-plated) |

| Manifold | Injection moulded (Trirex 3020U) |

| Inlet outlet thread | G1/4 |

| Screw | M3×16 Thread forming screw |